Working With Pex

The research is still incomplete on this matter but if you want to use PEX you may want to choose type B. PEX B is formed using Silane or Moisture Cure method.

Pex Pipe 101 All You Need To Know Bob Vila

Pex Pipe 101 All You Need To Know Bob Vila

Loggin to the Server and type in this command.

Working with pex. PEX is extremely sensitive to UV light. Anyone buying or working with PEX should know the differences so as to know how to select the proper tubing. Its crucial to take a mixing valve apart before soldering it.

Pex has so many advantages over copper its crazy that pex didnt catch on faster but then there would be a lot of unemployed plumbers I guess. Leave the cords on and unroll just the amount you need. If running vertically it should be supported every 4 to 6 feet.

One complaint about working with PEX is that the coils have a mind of their own. PEX-C is manufactured via an irradiation method. It is a form of flexible plumbing tubing used for both hot and cold water supply lines.

This is the most common PEX pipe type out there. After editing your config Save it. PEX stands for cross-linked polyethylene and is sometimes referred to as XLPE Polyethylene is composed of chains of ethylene molecules referred to as polymers hence poly-ethylene These polymers dont connect which.

To avoid this use bungee cords to help keep your coils in check. As soon as the banding is removed from the coils they tend to explode out in every direction. This means that it will naturally want to revert back into its original shape.

PEX may leach BPA and other toxic chemicals. PEX needs to be supported a minimum of every 32 inches when running horizontally. There are 3 types of PEX A B and C but type B is the only one that doesnt appear to have the leaching problem.

So for most jobs you will want to buy the 10-foot sticks of PEX instead of the coils. Thanks to its flexibility and ease of connection PEX is gradually becoming the preferred pipe for residential and commercial uses. PEX is a material that has memory to it.

Because its the stiffest version PEX-C is the most difficult to work with. Even plumbers who run miles of PEX every year often buy sticks than coils. Once it cools from soldering it can be safely connected it to the PEX water line.

Since you cant solder around the PEX piping use a fitting called a PEX 90 that sweats right into place on a mixing valve. The straps should be plastic or metal that is designed to work for plastic pipe. Can I use SharkBite fittings for anything other than potable water and radiant heating eg air gas oil etc applications.

If your coil comes wrapped in plastic dont remove it. You may have to pay a few cents more per foot and install a coupler or two but youll avoid frustration and kinks. Once I learned about pex I gave up working with copper piping and I love working with all types of metal.

Now rename the word Default to Owner and just make the letters are case sensitive like in the PEX file. This stiffness also makes it most prone to kinking as well as. But when I learned how to connect pex to a faucet I knew it was game over.

Also asked can you use PEX for compressed air lines. For most jobs youre better off buying 10-ft. So working with a coil of PEX is like wrestling with a giant Slinky.

PEX A is made using the Peroxide or Engel method. PEX plumbing pipe is a term that refers to cross-linked polyethylene. PEX is not meant to be pulled tight so leave slack for expansion and contraction.

No PEX pipe is not intended for compressed air applicationsI had pex in my last shop for six or seven years. PEX C is created using the Electronic Irradiation or Cold method of cross-linking. Remove any parts that might be.

PEX Connectors and Fittings. Working with a coil of PEX is basically akin to working with a big slinky. Make sure to not remove the space between otherwise It wont work So only delete the Symbol.

PEX Plumbing Disadvantages. Run the PEX tubing. Furthermore can SharkBite fittings be used for compressed air.

Pex Pipe 101 All You Need To Know Bob Vila

Pex Pipe 101 All You Need To Know Bob Vila

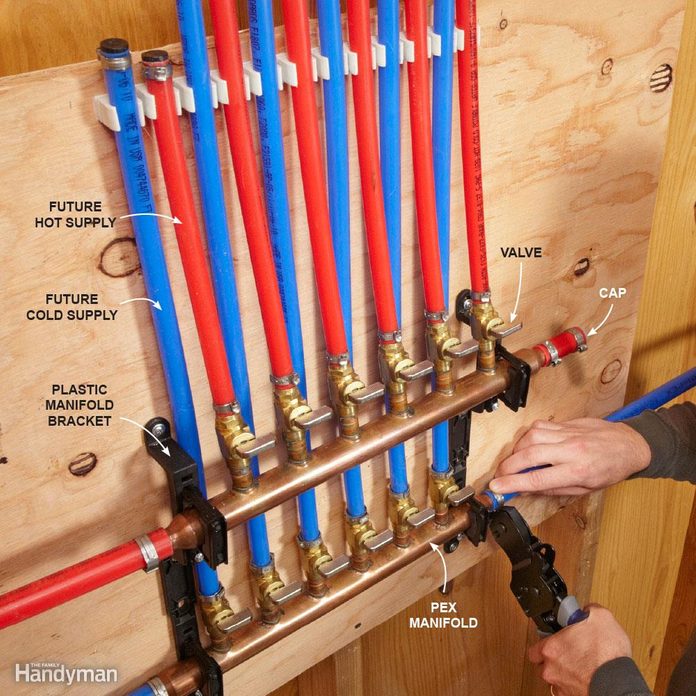

Pex Supply Pipe Everything You Need To Know Guide The Family Handyman

Pex Supply Pipe Everything You Need To Know Guide The Family Handyman

Working With Pex Pipes Youtube

Working With Pex Pipes Youtube

Connect Pex To Copper Replace Copper With Pex Sharkbite

Connect Pex To Copper Replace Copper With Pex Sharkbite

Three Designs For Pex Plumbing Systems Fine Homebuilding

Three Designs For Pex Plumbing Systems Fine Homebuilding

Plumbing Basics Working With Pex Plumbing With Nick Carpenter Lucas Lu Diy Plumbing Plumbing Pex Plumbing

Plumbing Basics Working With Pex Plumbing With Nick Carpenter Lucas Lu Diy Plumbing Plumbing Pex Plumbing

Plumbing With Pex Tubing Family Handyman

Plumbing With Pex Tubing Family Handyman

Working With Pex Pex Plumbing Diy Plumbing Water Heater Repair

Working With Pex Pex Plumbing Diy Plumbing Water Heater Repair

Pex Supply Pipe Everything You Need To Know Guide The Family Handyman

Pex Supply Pipe Everything You Need To Know Guide The Family Handyman

Pex Pipe 101 All You Need To Know Bob Vila

Pex Pipe 101 All You Need To Know Bob Vila

/PEXandCopper-565bd9275f9b5835e4707ec0.jpg) Copper Vs Pex And Push Fit Sharkbite Comparison

Copper Vs Pex And Push Fit Sharkbite Comparison

Pex Pipe 101 All You Need To Know Bob Vila

Pex Pipe 101 All You Need To Know Bob Vila

What Is Pex Pipe Pex Pipe Fittings Pex Pipe Problems How To Remove A Pex Fitting Cpvc Vs Pex Copper Vs Pex

What Is Pex Pipe Pex Pipe Fittings Pex Pipe Problems How To Remove A Pex Fitting Cpvc Vs Pex Copper Vs Pex

/BendPEXTubing90-DegreeJoint-c05aa26bcb2a49fe96c3e851a5efe9a4.jpg)

Comments

Post a Comment