Making Concrete Form

Were making some pilasters for a concrete fireplace surround but the same technique should apply to any small masonry project. Ad Build PHP form applications easily Forms Reports Grids Charts PDF.

To begin youll want to gather up all of the tools and materials necessary to successfully execute the construction of a standard concrete form.

Making concrete form. How Concrete is Made In its simplest form concrete is a mixture of paste and aggregates or rocks. The paste composed of portland cement and water coats the surface of the fine small and coarse larger aggregates. The first thing you should do is make sure your model your making a mold of is sealed.

This article will refer to a slab form wall forms have completely different requirements. When youre making small scale architectural elements out of concrete you could use a stick to make sure that the concrete is compacted into all of the voids but theres a better way. Building a straight form for concrete is fairly simple as long as the correct techniques are used.

Youve come to the right place to learn how to make a concrete form successfully. How to Make a Concrete Form. Ad Build PHP form applications easily Forms Reports Grids Charts PDF.

Casting concrete into rubber molds made with Smooth-On Rubber lets you make perfect copies. The best form for a particular project is often a function of the pour size the amount of concrete the form needs to retain and the pressure or weight that will be pushing against the form. Concreteshedslab concreteslabforshed mikedayconcreteIn this video Im going to show you how to form pour and finish a concrete slab for a shed.

How to Build Concrete Forms - YouTube. The depth and width of the concrete placement determine the bracing and forming material required. Learn about the different sizes o.

Concrete Mold Making Casting HowTos. Assemble your concrete form. While later on Ill also cover the alternatives lets start by taking a step-by-step look at how to create a concrete form from wood.

That way the latex rubber wont absorb into it making it tougher to peel off after your mother mold fiberglass shell is done. For example the typical concrete forms used for flatwork such as a patio driveway. Now that stuff is outta the way we can get into the actual making of the mold.

Through a chemical reaction called hydration the paste hardens and gains strength to form the rock-like mass known as concrete. Worlds Strongest Man Takes On The Recycling 15 - GEICO Insurance. For a 5-in-thick slab with thickened edges which is perfect for most garages and sheds 2x12 boards work best.

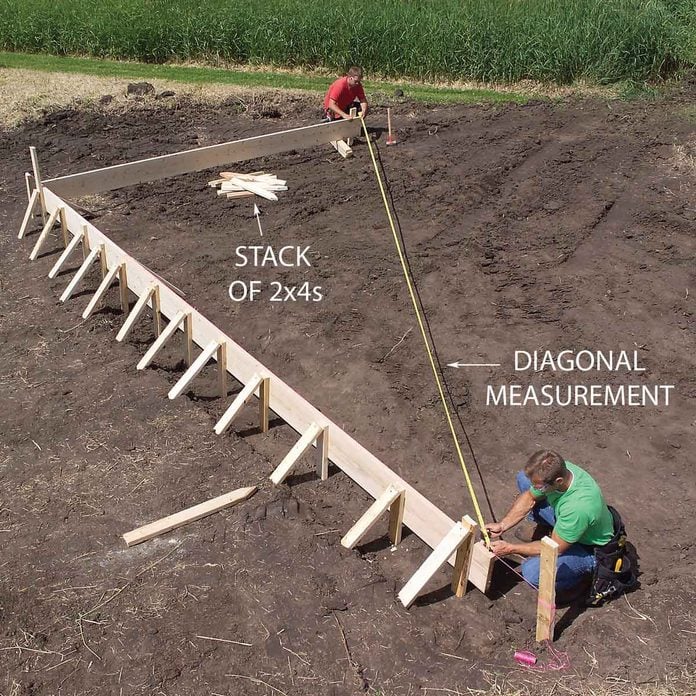

Cut a 2x12 to length or splice it with a cleat for one side of the concrete forms and nail it to a corner stake. Concrete casting pros from around the world know Smooth-On liquid rubber products as the industry standard for making rubber molds that have the abrasion resistance and tear strength needed to keep production moving. Level the 2x12 and nail it to the second corner stake.

Use screws and a power drill to attach each riser form board to your stringers. Start by choosing straight form boards. You can do this by laying each stringer form so the even bottom side of each stringer is flat on the ground and the zigzag side of the stringer is oriented with its points facing up.

Concrete forms are often categorized by where and how they are used. Wood concrete forms are the most widely used method for forming concrete slabs patios driveways walkwaysyou name it.

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms Types And Selection Of Concrete Forms

Concrete Forms Types And Selection Of Concrete Forms

Building Concrete Form And Pouring A Slab Youtube

Building Concrete Form And Pouring A Slab Youtube

How To Prepare A Site For Concrete Base Forms And Rebar

How To Prepare A Site For Concrete Base Forms And Rebar

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

How To Build A Straight Form For Concrete 6 Steps With Pictures

How To Build A Straight Form For Concrete 6 Steps With Pictures

Jrl Woodworking Free Furniture Plans Free Furniture Plans Concrete Forms Free Furniture

Jrl Woodworking Free Furniture Plans Free Furniture Plans Concrete Forms Free Furniture

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

How To Build Concrete Forms Youtube

How To Build Concrete Forms Youtube

Forming Concrete With Plastic Forms Youtube

Forming Concrete With Plastic Forms Youtube

Concrete Forms Forming Concrete With Wood Forms Youtube

Concrete Forms Forming Concrete With Wood Forms Youtube

Concrete Forms Types And Selection Of Concrete Forms

Concrete Forms Types And Selection Of Concrete Forms

Comments

Post a Comment