Float Concrete Slab

Concrete used for visible projects such as driveways patios and sidewalks often requires finishing. How to power float a concrete slab.

Floating Concrete Slab Details Page 1 Line 17qq Com

Floating Concrete Slab Details Page 1 Line 17qq Com

An object will sink if its more dense than the water.

Float concrete slab. There are two methods for finishing a concrete slab floating it smooth or brooming. A wet coarse broom is lightly dragged over the partially set up cement. The job must be done right after screeding because the concrete will still be wet enough to shape.

A 3-12 foot wide magnesium bull float. Once the surface has been floated the blades are angled to suit the concrete and achieve the specified finish. The main application of floating slabs is to use as a base foundation for sheds manufacturing workshops home additional room or garages.

This is how concrete can float. Floating usually starts at one end of the slab and moves to the other. After pouring the concrete and screeding it level the bull float is the first tool we use when finishing the slab.

More than just wining and dining. We chose brooming because we wanted a non-slip floor even in the wintertime. Concrete floating slabs can and in areas that experience freezing temperatures should be insulated.

The speed should be slow and consistent. Finishing is a process that gives a concrete surface the desired smoothness texture and durability. When going over the concrete we try and keep float must be kept as flat as possible to prevent the concrete from sealing prematurely.

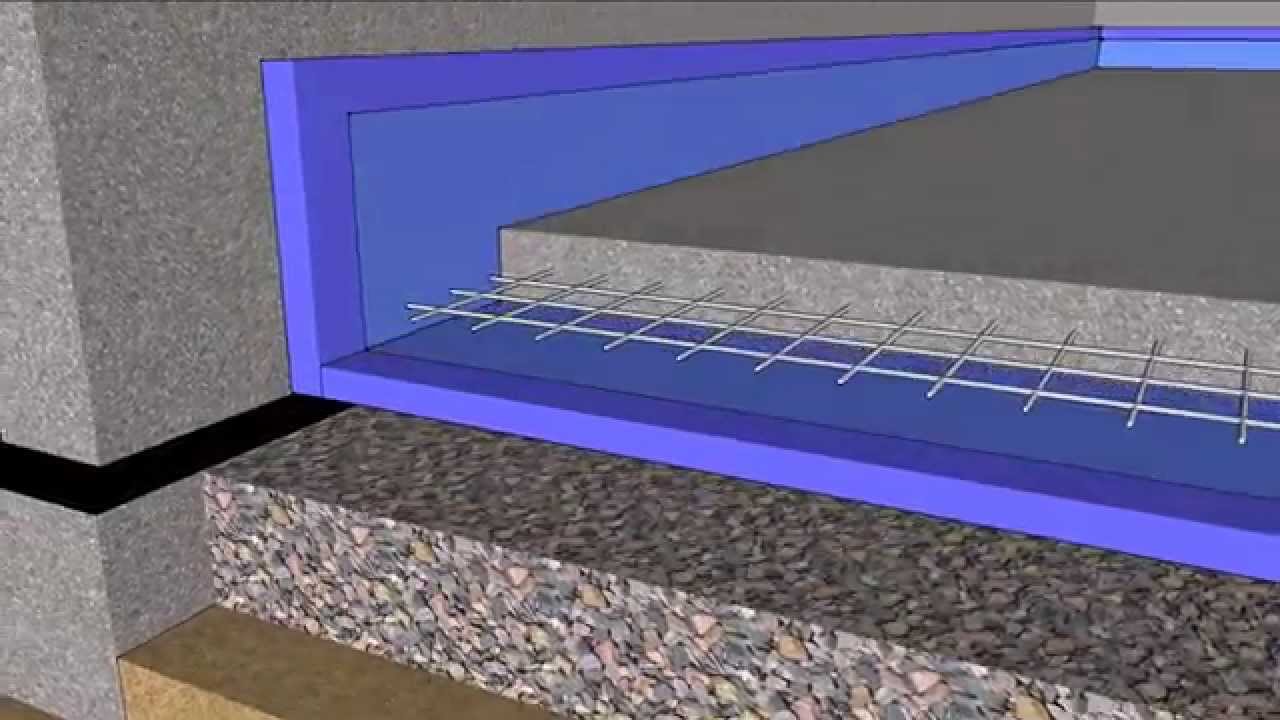

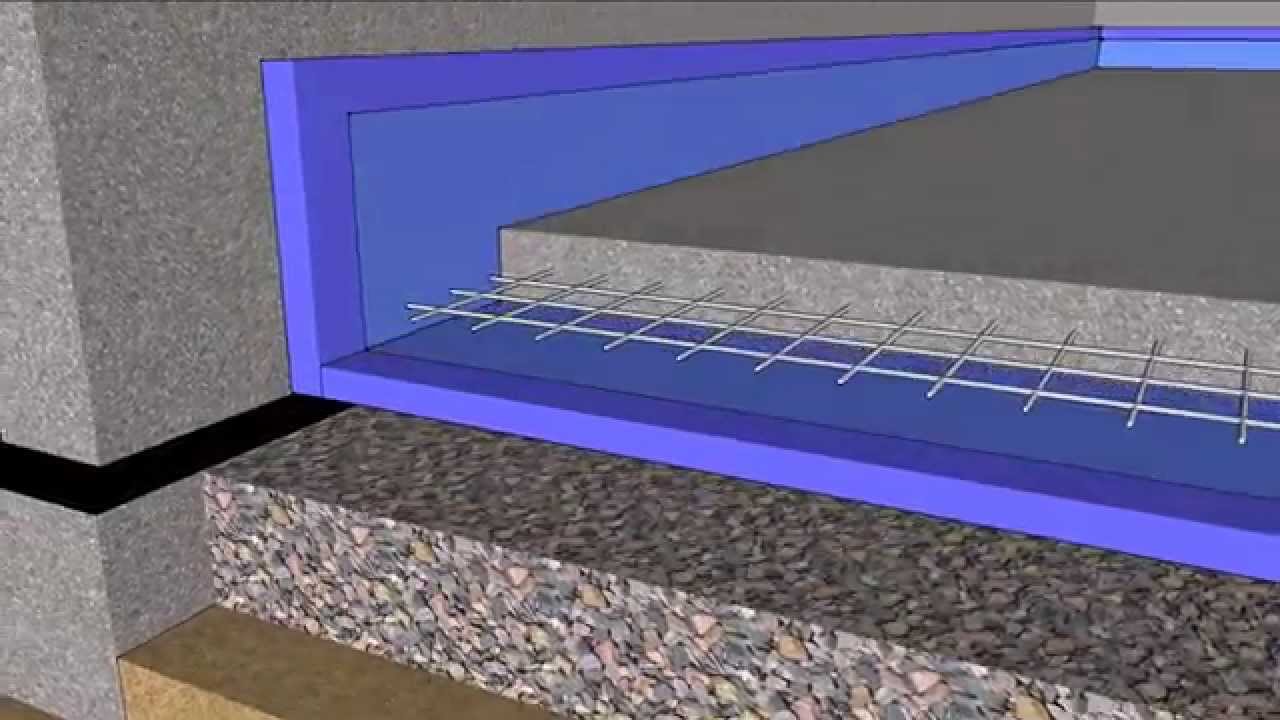

Nowadays standard power float includes a float pan and a finishing blade to soften concrete slabs. The slabs have a thickened reinforced perimeter but no frost footings. It is a poured cement slab that has two deep edges that go just below the frost line in northern climates.

The foundation actually does float on the earth and moves as temperatures compact and expand the soil. Floating slabs are concrete slabs that are laying over the ground without any kind of anchoring as if it simply sits on it and floats. How to power float the concrete slab.

If it has an equal density it will neither sink nor float. A bull float is a tool used for finishing concrete. Images and a video showing the process of a Concrete slab construction with 3mm crushed glass tamped into the RC 25 fibre concrete a black cement dye will be added once the power float pan is able to be positioned on the slab.

Any object including concrete will float if its less dense than the water its placed in. First attach the float pan to the power float. The length of the handle allows us to reach out onto a concrete slab.

Floating slab as the name tells it resembles a plate that is simply laid over water with no kind of connection between them. A floating slab is the basic foundation structure used for buildings that do not have basements garages sheds barns and even some homes in high water table or coastal areas. I am building the gar.

This allows it to float on top of the concrete slab. Concrete is our playground. Floating slabs are used as the foundations for a variety of structures including sheds car garages additions cottages and much more.

A floating foundation is the foundation of a building that does not use footings. Monolithic Slab Monolithic means all in one pour so the foundation is constructed in one single pour that is made up of a concrete slab with thicker areas under load bearing walls and all perimeter edges to take the place of footers. The first finishing tool on the slab pushes down rocks and brings the cream to the top of the concrete surface After pouring the concrete and screeding it level it is time to begin finishing the slab in this case a small driveway addition.

The floating slabs are called as monolithic slabs as they have no connection with the foundation. The density of water is generally 624 lbsft 3 but that varies based on its salt content. They are called floating because they are allowed to move above the frost line as a.

This is how you work with concrete power float finish with two attachments. A bull float is used to level and smooth freshly poured concrete. The density of concrete can be altered by either changing its mass its shape or both.

Forged from the past shaped by the future. The main application of floating slabs is to use as a base foundation for sheds manufacturing workshops home additional room or garages. FLOAT concrete tiles and contemporary furniture.

I this video Im showing a small 23x23 floating concrete slab I built this is just a DIY the slab has a permit and passed inspection. How Do We Use A Bull Float To Finish Concrete. Floating slabs are concrete slabs that are laying over the ground without any kind of anchoring as if it simply sits on it and floats.

Once the concrete has been poured pull the machine in front of you gradually from one side of the slab to the other over to the side slightly and then again in a new row. Floating slabs are concrete slabs that are laying over the ground without any kind of anchoring as if it simply sits on it and floats. A power float is a machine used by hand either with the operator walking behind it or riding on a larger one if the project requires it in order to produce a smooth dense and level finish to a newly-laid onsite poured concrete floor.

Float pans generally do a pretty good job of flattening and levelling the floor while allowing moisture to evaporate at a reasonably steady rate. Minimalist design meets function. Float pans are used in the early stages as their large flat surface distributes the machines weight over a larger area.

The operator holds the float at waist-height and moves backwards so that the float removes their footprints.

Final Concrete Layer Of The Floating Floor Download Scientific Diagram

Final Concrete Layer Of The Floating Floor Download Scientific Diagram

Frame A Levitating Ceiling And A Floating Concrete Slab

Frame A Levitating Ceiling And A Floating Concrete Slab

Floating Concrete Slab Details Stairs Pinned By Www Modlar Com Foam Roofing Concrete Concrete Floors

Floating Concrete Slab Details Stairs Pinned By Www Modlar Com Foam Roofing Concrete Concrete Floors

Mounting Example Of A Floor Drain With A Concrete Floating Screed 1 Download Scientific Diagram

Mounting Example Of A Floor Drain With A Concrete Floating Screed 1 Download Scientific Diagram

What Is Floating Slab Floating Slab Construction How To Build A Floating Slab Advantages Disadvantages Floating Slabs

Basement Floating Slab In 4d Youtube

Basement Floating Slab In 4d Youtube

Learn How To Build Floating Concrete Slab Diy Rebar

Acoustic Floating Floors Farrat Concrete Floating Floor System Floating Floor Concrete Sound Insulation

Acoustic Floating Floors Farrat Concrete Floating Floor System Floating Floor Concrete Sound Insulation

What Is Floating Slab Floating Slab Construction How To Build A Floating Slab Advantages Disadvantages Floating Slabs

What Is Floating Slab Floating Slab Construction How To Build A Floating Slab Advantages Disadvantages Floating Slabs

What Is Floating Slab Floating Slab Construction How To Build A Floating Slab Advantages Disadvantages Floating Slabs

What Is Floating Slab Floating Slab Construction How To Build A Floating Slab Advantages Disadvantages Floating Slabs

Floating Slabs Waddell Engineering Ltd

Floating Slabs Waddell Engineering Ltd

Acoustic Floating Floors Farrat Concrete Floating Floor System Isolamento Acustico

Acoustic Floating Floors Farrat Concrete Floating Floor System Isolamento Acustico

Comments

Post a Comment